BISTABLEDOME.COM

Sensing shape and motion of flexible surfaces, controlling and shaping thin high strength metals, and a pump that pumps when bent.

Flex-actuated overlapping bistable domes (OBDs) are a simple low-profile structure for sensing, controlling, and utilizing flexural forces

Pairing OBD technology with recent advances in AI can help create low cost paper thin shape sensors and control shape in thin high strength metal .

OVERVIEW:

For these purposes a flex-actuated bistable dome is a shallow indentation in thin strong material formed so that when the material around a dome is bent toward the same side as the dome it will buckle and snap toward the outside of the curvature. This simple one-piece structure can be made in a wide range of scale and materials. Dome displacement may not be much more than the material thickness. Harder materials minimize/eliminate absorption of flexural forces. Overlapping bistable domes (OBDs) form a very low profile 3 dimensional structure stiffer than the original flat material. OBDs share flexural forces that switch/invert individual domes. When a row of OBDs is formed in a band of material of the same width, the edges of the band buckle slightly between domes and become structurally shorter. The buckling allows dome formation in hard materials with less presure. The band of material through the middle of a row of OBDs (through the tops of the domes) is longer and wants to occupy a larger radius. When the edges of a row of equally bistable domes are flattened the domes want to alternate orientation to compensate. When the row/structure is bent domes neutralize flexural forces by buckling and switching sides. When the edges are held in a stiffer construction the domes will switch in numbers proportional to curvature. Closely-packed arrays of OBDs can be formed in thin hard materials with low force/pressure beginning at an edge. Succeeding OBDs absorb/compensate for buckling and distortion caused by preceeding OBDs. Within minimum radius limits OBD structures can be used to force flat material into desired curvatures by controlling the characteristics of individual OBDs in formation (height, diameter, bistable tendency, etc). A printer that can print OBDs with different characteristics, like an impact printer for OBDs instead of letters could 'print' shape in thin high strength steel. Low pressures required for forming OBDs may allow use of common 3D printing materials to create stamping and rolling tools. When two bands of .03" 302 stainless steel (same as in video) are compared for resistance to deformation, the OBD row, while weighing the same and being only 2x thicker in profile, resists approximately 4x as much weight before collapse.

Contact digital bend and shape sensor

Paper thin flex-actuated bistable domes can be used as switches to digitize shape and motion. Suitable for paper thin flex circuitry construction. Can simultaneously tell a computer where, how much, and in which direction it is bent (ie. up/down), regardless of its position in space.

Applications range from simple flex sensitive switches and bend sensing to multidimensional tactile shape sensing and object recognition. Can be used for monitoring curvature, displacement, impact, force, motion, pressure, timing, position, weight, fluid motion.

Rghti: Low resolution shape sensor prototype. 5 seperate OBD switch rows wired directly to LED lights. OBD rows are suspended by their edges in a stiffer overall construction and individual OBDs are free to respond to flexture. All switches are off in the convex unflexed position.

US Patent # US Patent # 5563458

See more at Shape Sensor.

Flex actuated overlaping bistable dome array

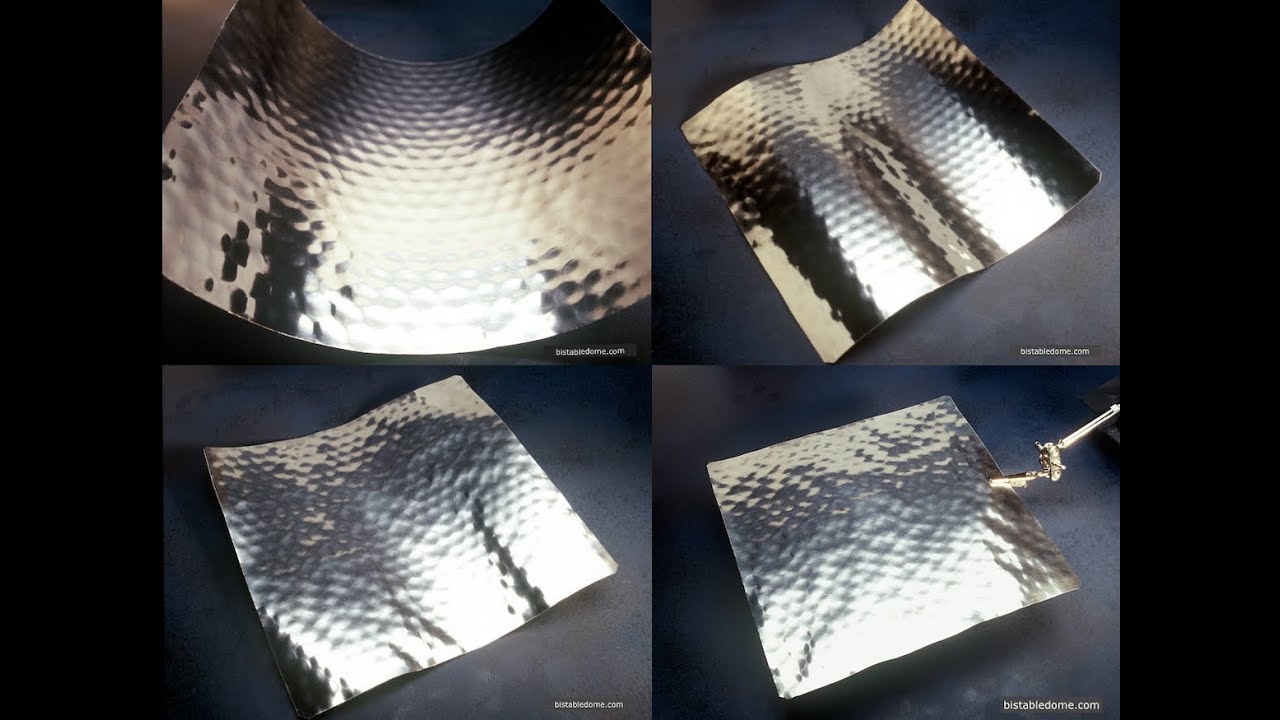

Controlling springback and creating shape memory in thin high strength steel such as .006" 302 stainless. See video of flex actuated overlapping bistable domes and arrays in motion. Arrays of closely packed shallow overlapping bistable domes constructed in thin high strength steel form a stiffer structure two or three times the original thickness that can be bent and rebent with little or no springback. Wherever it is bent the local bistable domes adjust their orientations incrementally to neutralize flexural forces and hold the new shape. Similar bistable domes can be used to create flexural forces in high strength steel while in a flat plane so that it has a predisposition to assume a desired shape as soon as it is freed to do so. Overlapping bistable domes may help in prototyping and reduce stamping and tooling requirements. It also presents opportunities for stronger and lighter construction that may improve fuel efficiency and help the transportation industry, for example, reach higher environmental stadards in response to climate change.

Artificial intelligence and OBDs

Artificial intelligence can play a crucial role in developing and enhancing OBD applications. Here are a few ways AI can assist:

Pattern recognition: AI algorithms can be trained to recognize and correlate patterns of OBDs with specific shapes, radii, orientations, and other parameters. This can help in accurately digitizing and interpreting the input from OBD-based shape sensors.

Predictive modeling: AI can analyze the behavior of OBDs when bent and predict their response based on various factors such as material properties, geometries, and applied forces. This can aid in designing more efficient and predictable OBD structures.

Optimization and simulation: AI algorithms can be used to optimize the arrangement and distribution of OBDs in arrays for specific applications. By simulating different configurations, AI can help identify the most effective layouts for printing shapes or strengthening thin hard metals.

Material research: AI can assist in exploring new materials or combinations to improve the performance of OBDs. By analyzing vast amounts of data and conducting virtual experiments, AI can help identify materials with desired properties, such as flexibility, durability, and bistability.

Rapid prototyping: AI can facilitate the rapid design and prototyping of OBD-based structures. By generating and evaluating multiple design options, AI can help accelerate the development process and reduce the need for physical iterations.

Overall, AI can contribute significantly to the development of OBD technology by providing insights, automating processes, and enabling more efficient experimentation and optimization.

Pattern recognition: AI algorithms can be trained to recognize and correlate patterns of OBDs with specific shapes, radii, orientations, and other parameters. This can help in accurately digitizing and interpreting the input from OBD-based shape sensors.

Predictive modeling: AI can analyze the behavior of OBDs when bent and predict their response based on various factors such as material properties, geometries, and applied forces. This can aid in designing more efficient and predictable OBD structures.

Optimization and simulation: AI algorithms can be used to optimize the arrangement and distribution of OBDs in arrays for specific applications. By simulating different configurations, AI can help identify the most effective layouts for printing shapes or strengthening thin hard metals.

Material research: AI can assist in exploring new materials or combinations to improve the performance of OBDs. By analyzing vast amounts of data and conducting virtual experiments, AI can help identify materials with desired properties, such as flexibility, durability, and bistability.

Rapid prototyping: AI can facilitate the rapid design and prototyping of OBD-based structures. By generating and evaluating multiple design options, AI can help accelerate the development process and reduce the need for physical iterations.

Overall, AI can contribute significantly to the development of OBD technology by providing insights, automating processes, and enabling more efficient experimentation and optimization.

Bistable dome pump - flexible pump that pumps when bent

A very simple pump that can utilize a wide range of natural or mechanical motion. Small or large scale wind and wave power renewable energy applications. Possibilities for water and pressure supply, desalination, mariculture/aquaculture, sediment relocation, erosion control, re-oxygenation, oil spill management, medical, lubrication, etc. Low cost appropriate technology applications. US Patent # 6132187. Flex-actuated Bistable Dome Pump (expired). (Use contact address below).

Video below: demonstration of behavior of rows and arrays of OBDs

Video can’t be displayed

This video is not available.

OBD Shape sensor

OBD Array in .006" 302 stainless steel

OBD row in .03" 302 stainless steel

Dome height may be less than material thickness but OBDs add significaant stiffness

Bistable dome pump